In San Francisco, the sounds of construction once again fill the air. Detroit auto workers have returned to the assembly line. And Pittsburgh residents can even enjoy a round of golf — provided they maintain a six-foot distance.

After nearly twelve weeks of lockdown, a graphic from the Washington Post shows that most states have already begun lifting restrictions to varying degrees. How and when businesses transition out of lockdown and reopen depends on a number of factors, including their location and industry. But we’re starting to see some early signs of businesses coming back to life.

The road to recovery

In the construction industry, for example, the path forward is starting to look a little brighter. During the COVID-19 shutdown, many contractors saw projects put on hold or canceled. According to a survey conducted in March by the Associated General Contractors of America, 28% of contractors said they had been directed to halt or delay projects. In other cases, customers have pushed back bidding or paused projects to save money. Ohio State University, for example, paused work on 11 construction projects to preserve liquidity. Some contractors have also reported disruptions due to shortages of building supplies and workers, as well as delays in obtaining necessary permits and inspections.

Now, with states loosening restrictions, construction activity is picking back up. Many states are allowing contractors to finish projects that were suspended. Delayed new construction projects are being finalized and scheduled. And bidding opportunities are ticking up. With the increase in activity, the sight of masks and social distancing will become as commonplace on the job site as hard hats and safety vests.

Manufacturers are upbeat about the future as well. Despite supply chain disruptions and significant changes to operations, nearly all of the 700 manufacturers surveyed by SME stated that their company was still operating in some capacity. In fact, half said they were still fully functional while only 8% were completely shut down.

Some manufacturers have responded to the crisis by pivoting to produce essential goods such as PPE and medical supplies. General Motors, for example, recently delivered its first batch of ventilators. Here at Safeguard, we’ve created new social distancing signs to convey safety messages — in addition to continuing to fulfill our role as a critical supplier to our nation’s essential industries.

As the U.S. and other countries reopen, some manufacturers are starting to see demand for their products pick back up. Increased lead times are expected as manufacturers address the effects of the virus on their suppliers, workers, and operations. However, over two-thirds of manufacturers said they are optimistic that the industry will recover to its pre-COVID-19 level of production by the end of 2020.

In other industries, the future is less certain. Bars, restaurants, gyms, and movie theaters are keeping their doors shut or offering limited services. Schools and universities remain closed for the foreseeable future. Officials at California’s public universities, for example, say it’s not likely students will return to campus this fall. Venues with large public gatherings, such as theme parks, professional sports, and entertainment arenas, are weighing their options for the rest of 2020. So are hotels, resorts, and cruise operators.

Beyond protecting people and resuming normal operations, one major concern when it comes to reopening businesses is cost. Nearly every industry has taken a hit, and cash and capital remain tightly scrutinized. Businesses may be able to reduce their expenses without sacrificing safety by strategically reducing non-essential spending — say, for office space and leased equipment.

Similarly, they may be able to preserve liquidity by delaying or canceling capital improvement projects and instead selecting the most impactful facility improvement and maintenance projects. For example, we’ve seen businesses using our retrofit anti-slip products to extend the life of ladders, ramps, and walkways rather than pay to replace them.

The road to reopening is a bumpy one, but we can get there if we keep safety at the forefront. At Safeguard, we’re here to support you as you continue essential operations or plan for the future. Contact us to speak to one of our experienced team members today.

Manufacturers are upbeat about the future as well. Despite supply chain disruptions and significant changes to operations, nearly all of the 700 manufacturers surveyed by SME stated that their company was still operating in some capacity. In fact, half said they were still fully functional while only 8% were completely shut down.

Some manufacturers have responded to the crisis by pivoting to produce essential goods such as PPE and medical supplies. General Motors, for example, recently delivered its first batch of ventilators. Here at Safeguard, we’ve created new social distancing signs to convey safety messages — in addition to continuing to fulfill our role as a critical supplier to our nation’s essential industries.

As the U.S. and other countries reopen, some manufacturers are starting to see demand for their products pick back up. Increased lead times are expected as manufacturers address the effects of the virus on their suppliers, workers, and operations. However, over two-thirds of manufacturers said they are optimistic that the industry will recover to its pre-COVID-19 level of production by the end of 2020.

In other industries, the future is less certain. Bars, restaurants, gyms, and movie theaters are keeping their doors shut or offering limited services. Schools and universities remain closed for the foreseeable future. Officials at California’s public universities, for example, say it’s not likely students will return to campus this fall. Venues with large public gatherings, such as theme parks, professional sports, and entertainment arenas, are weighing their options for the rest of 2020. So are hotels, resorts, and cruise operators.

Paving the way forward

Once businesses get on the path to reopening, they will have to navigate a complex new reality. The immediate threat of COVID-19 is far from over, and protecting employees and customers will remain the top priority. Many factors will need to be considered, including cleaning and disinfection, social distancing, and ongoing monitoring. To that end, the CDC has issued guidelines to help businesses reopen safely.Beyond protecting people and resuming normal operations, one major concern when it comes to reopening businesses is cost. Nearly every industry has taken a hit, and cash and capital remain tightly scrutinized. Businesses may be able to reduce their expenses without sacrificing safety by strategically reducing non-essential spending — say, for office space and leased equipment.

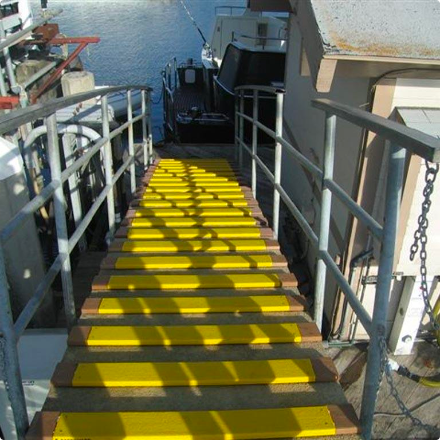

Similarly, they may be able to preserve liquidity by delaying or canceling capital improvement projects and instead selecting the most impactful facility improvement and maintenance projects. For example, we’ve seen businesses using our retrofit anti-slip products to extend the life of ladders, ramps, and walkways rather than pay to replace them.

The road to reopening is a bumpy one, but we can get there if we keep safety at the forefront. At Safeguard, we’re here to support you as you continue essential operations or plan for the future. Contact us to speak to one of our experienced team members today.