Is your facility up to safety standards? Most manufacturing facilities are shut down between Christmas and the New Year, creating the perfect opportunity for your maintenance team to take a step back and thoroughly evaluate the safety and general cleanliness of your facility. Due to manufacturing schedules being halted and workers being away, maintenance crews have ample time and space to properly clean and ensure the facility is up to safety standards without obstructing production activities.

But even outside of this holiday time period, there are steps your maintenance team can take any time of year to improve facility cleanliness – and thereby reduce slips and falls.

In this blog post, we’ll take a look at what you and your team should consider when evaluating your facility’s cleanliness, and how failure to properly do so can result in slip and fall safety hazards.

What to Evaluate to Prevent Slips and Falls – and How to Clean Effectively

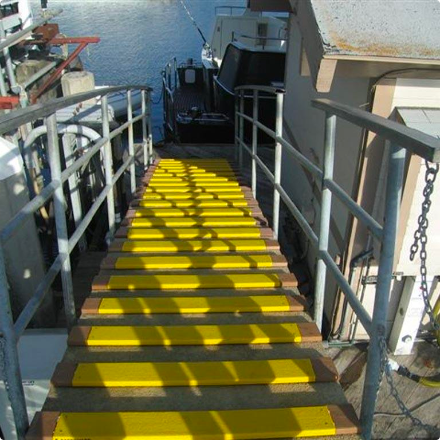

Evaluate All Floors, Stairwells, and Ladders – but Especially High-Traffic Surfaces

The number one culprit of slips and falls on a facility’s floors, stairwells, and ladders is the buildup of dirt, grime, grease, fluids, and other elements on these surfaces.

Whether your crew has high-quality anti-slip covers throughout your plant or not, the failure to properly clean surfaces can result in serious safety hazards. Anti-slip covers, like walkway and ramp covers, step covers, and ladder rung covers, can provide the friction necessary to prevent slips and falls.

If you don’t use anti-slip covers at your facility, it’s a good idea to consider investing in them for that first line of protection. But it’s also a good idea to ensure your maintenance crew consistently cleans these surfaces – whether they have anti-slip covers or not – to prevent grime buildup and safety hazards.

Effective Cleaning Tips for Floors and Other Surfaces:

- Monthly cleaning of anti-slip covers: If you have high-quality anti-slip covers installed at your facility, we recommend cleaning them at least once per month.

- Frequent cleaning of surfaces without anti-slip covers: If you don’t have anti-slip covers installed at your facility, you should be cleaning your floors, stairwells, ladders, and walkways every ten minutes or so. There are both automated and manual solutions for this.

- Automated cleaning options: Automated floor scrubbers can be used to clean parts of facilities where anti-slip products aren’t being used, but they’re known for requiring frequent maintenance, which can become very costly.

Properly Clean Anti-Slip Products

Slips and falls can effectively be prevented with the proper cleaning of anti-slip covers. Consistent monthly cleaning is important, but making sure to remove dirt and grime from anti-slip covers and other products increases safety and decreases downtime.

One of the top reasons anti-slip covers or mats start to fail is because they have a layer of grime over their gritted sections. This poses a slip and fall risk and can create a hazardous environment for your team. The good news is, it’s extremely simple to clean products like ladder rung covers, walkway and ramp covers, step covers, landing covers, direct gritting, and other anti-slip products.

Effective Cleaning Tips for Anti-Slip Products:

- What tools to use: Use a stiff bristle brush with hard, plastic bristles to brush away the grime that’s stuck in between the different bumps and grooves on the surface of the product.

- What cleaning agents to use: A mild detergent like Dawn dish soap and warm water can be used with the brush to wipe away any grease or grime.

- Choose portable anti-slip products: In situations where water can’t be used inside of a facility or around certain machines, anti-slip mats should be used because they can be easily taken outside to be cleaned.

- Be mindful not to use too much pressure: When using high-pressure hoses or washers, start using the lowest setting and only increase pressure if the grime isn’t being removed. High-pressure settings can actually remove the gritted surface itself. When cleaning mats are secured to a surface, it’s important not to spend too much time cleaning the edges where sealants are used. If sealants are accidentally removed during the cleaning process, they must be resealed again.

Remove and Replace Anti-Slip Tape – Don’t Clean It

Anti-slip tape is usually placed in areas with less traffic and is a great temporary solution that’s used in many facilities.

However, tape is something you shouldn’t bother cleaning, and it can easily turn into a huge slip and fall hazard when it isn’t replaced in a timely manner or when it gets wet. How often tape should be replaced depends on how heavily trafficked the area is. In areas that experience heavy traffic, foil backed anti-slip tape usually lasts up to a month. If this tape gets wet, then its longevity is cut in half and it must be replaced within two weeks.

Also make sure to remove and replace your anti-slip tape as soon as it begins to peel.

Take the Necessary Steps to Clean Your Facility and Prevent Slips and Falls

All manufacturing facilities should share the same priority of keeping their team members safe on the job.

Taking preventative measures to ensure slips and falls don’t happen inside of your plant is incredibly important. Consistently evaluating items like floors, ladders, and even anti-slip tape to ensure surfaces remain clean and safe can prevent slip and fall hazards, downtime, and machine damage.

Keeping this checklist of items in mind and taking the extra steps to clean your space will have a positive, lasting effect on your facility’s safety. If you don’t have anti-slip covers, mats, or tape in your facility, we suggest you look into investing in some for the sake of your crew’s safety and the functionality of your machines and equipment.

Take the step to reduce slips and falls in your facility and request a consultation today.